· News

Flexible and autonomous: ROBDEKON’s decontamination robots

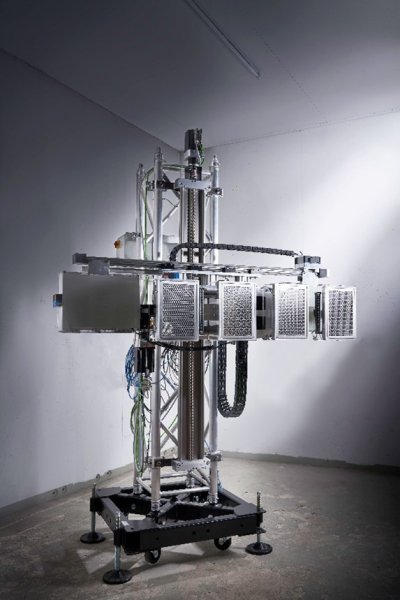

In order to automate complex processes during the dismantling of nuclear facilities, the Institute for Technology and Management in Construction Operations at the Karlsruhe Institute of Technology (KIT-TMB) is developing a mobile platform, called DekontBot, with two different tool attachments in ROBDEKON. This allows both contamination measurements and the milling of wall surfaces to be carried out largely autonomously.

Contamination array for clearance measurement

One tool is the contamination array, which measures radioactive contamination on wall surfaces. It consists of a laser scanner that records the surface geometry, four contamination detectors and several linear units to enable the detectors to be moved horizontally and vertically. It also has an impact point detection system. This means that it can carry out the entire (clearance) measurement process - which was previously carried out manually - automatically and document the results. Humans can monitor the process and remain able to interact at all times.

Milling attachment for automatic removal and suction up to a height of 8 meters

The contamination array was designed as an attachment for DekontBot - a mobile platform for various decontamination steps that can transport tools within a property to the specific site and can also reach higher locations using a lifting attachment. Another tool for DekontBot is a special milling machine for automatically milling away radioactive contamination from wall surfaces.

A new feature of the milling robot makes it possible to extract milled material at a lifting height of up to 8 meters. An sophisticated hose guide using a manipulator makes it possible to move the suction device up and down to the milling site - flexibly and precisely. This opens up new possibilities for decontamination at greater heights.

Verbesserte Sicherheit, Teleoperation und Semi-Autonomie

Another goal is to mill off curved surfaces, after the researchers taught DekontBot to process flat walls in the first funding phase of ROBDEKON. To this end, adjustments are being made to the milling head.

DekontBot is also making progress in terms of safety, autonomy and flexibility: as part of continuous testing and optimization, additional sensors have been installed to further improve the safety system and eliminate potential sources of error. Following the upcoming release for teleoperation modes, the system will be able to be controlled remotely. Moreover, the researchers are working on semi-autonomous driving: This involves automatically calculating the path from a starting point to various hotspots, then a human operator approves the proposed journey of the 2.6-ton robot.