German Research Center for Artificial Intelligence GmbH

The German Research Center for Artificial Intelligence (DFKI) GmbH was founded in 1988 as a non-profit public-private partnership (PPP). It is located in Kaiserslautern, Saarbrücken and Bremen. DFKI is Germany’s leading business-oriented research institution in the field of innovative software technologies based on artificial intelligence methods.

The Robotics Innovation Center (RIC) is part of the Bremen location. Here, scientists under the direction of Prof. Dr. Dr. h.c. Frank Kirchner, develop mobile robotic systems that are used for complex tasks on land, at sea, in the air and in space.

Research focus in ROBDEKON

DFKI RIC is working on the sub-project "Mobile semi-autonomous robots in deconstruction scenarios under human coordination". Robots and humans should work together in dismantling or decontamination processes of industrial plants and complement each other. For this purpose, the developed technology must allow close cooperation between humans and robots on site, but also in tele-operation scenarios.

The RIC contributes its many years of expertise in the development of mobile autonomous robots specifically for use in hazardous environments such as space or deep sea, since systems in contaminated areas have to meet very similar requirements.

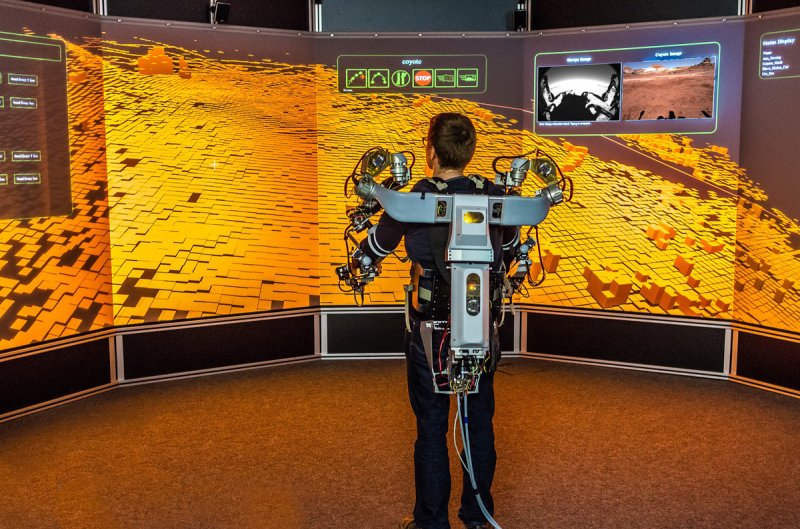

Within ROBDEKON, the DFKI is dealing with different topics. The primary goal is to keep humans distanced from potential hazards. The development of a control station is of great importance for this. Due to the large number of possible tasks, it can be assumed that not all tasks can be performed autonomously by a system. Rather, it will be important to automate certain subtasks while always giving humans the opportunity to intervene. In addition to the stationary control station, the systems can also be controlled from a mobile control station that is not tied to a laboratory. The visualization of several robot systems and their sensor data in a virtual 3D environment is of great relevance here, so that the operator gets as realistic an impression of the environment as possible. Depending on the scenario and the task of the respective system, it is possible to change the input devices on the fly. The integration of external data streams into the control station to put operators in the situation on site and thus realize a higher degree of immersion is also part of the work.

Completed are the development and implementation of an autonomy concept for construction machinery. This is demonstrated by the modification of an agile walking excavator called ARTER. ARTER is based on a Menzi Muck M545 walking excavator, which was adapted for teleoperated and autonomous operation. For this purpose, various PCs and programmable logic controllers (PLC) were installed and electrical control valves were added. Additional sensors installed in the lifting cylinders and at important joints provide information about ARTER's system status. A multi-layered safety concept in hardware and software ensures that the excavator can be handled safely at all times during development, experiments and operation.

ARTER captures its environment with the help of its multiple sensors and provides an external control station with a comprehensive situation picture of itself, its environment and its mission. If necessary, the robot excavator can be teleoperated via gamepads, two joysticks or with a virtual reality headset. The control in a three-dimensionally generated image of its environment creates a completely new control approach, since perspective, size ratio, environmental information and force feedback can be freely selected.