· News

GammaBot on an exploratory tour of the Mülheim-Kärlich nuclear power plant

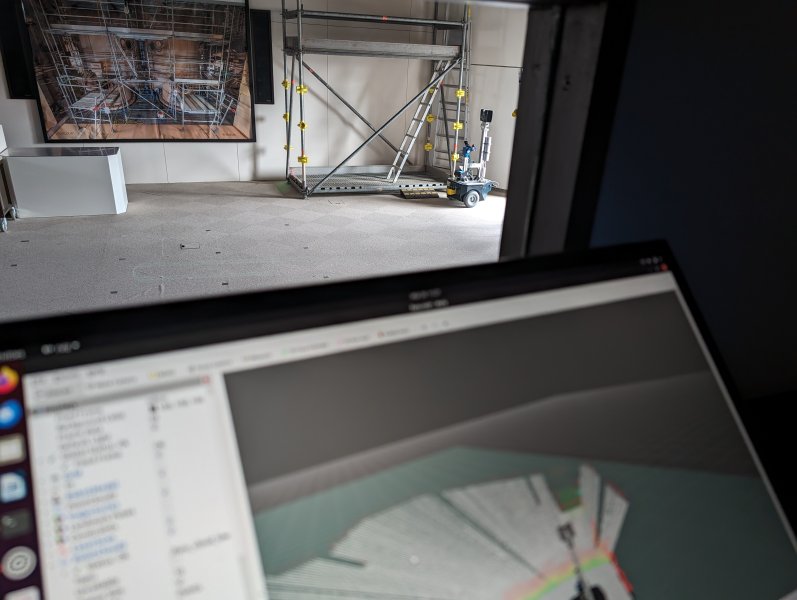

GammaBot has completed test runs on the site of the Mülheim-Kärlich nuclear power plant: The robot from Karlsruhe University of Applied Sciences (HKA) autonomously explored a test room. The practical test was carried out together with the Institute of Technology and Management in Construction at the Karlsruhe Institute of Technology (KIT-TMB) and Kraftanlagen Heidelberg (KAH).

During the test run, GammaBot successfully demonstrated its spatial exploration and data acquisition capabilities. The practical application was part of the ongoing tests in the pilot phase of ROBDEKON. The aim of these tests is to evaluate and further develop the applicability and effectiveness of the robots in real operating environments in order to increase the safety and efficiency of the technology for practical applications - in this case, the dismantling of nuclear power plants.

During the visit of the ROBDEKON researchers, the robot Adrian, an internal development of the nuclear power plant, was also presented. It specializes in autonomous measurements of the local dose rate, documentation of the measurement results, the creation of a spatial map and the algorithmic calculation of a measurement grid. This resulted in an exciting and constructive exchange about the technical requirements and possible synergies between the two robotic systems. GammaBot also offers the option of local dose rate measurement, documentation and integration into the 3D model which will be used in future pilots where a local dose rate is expected.

Further tests are planned in which GammaBot will cooperate with the KIT-TMB's DekontBot. In these tests, GammaBot will create a detailed 3D model of the test area and then transmit it to the DekontBot for specific machining processes. The results and findings of these and future tests will contribute significantly to the further development and optimization of the technologies used. The research groups and companies involved are looking forward to further tests and developments in this area with great interest.