· News

ROBDEKON showcases state of development – Progress in decontamination tasks: Robots have learnt new capabilities

In 2018, the ROBDEKON competence center (robotic systems for decontamination in hazardous environments) started operations. After three years of work, a regular review was due - on this occasion, the ROBDEKON partners in Karlsruhe and Bremen presented the state of their developed technology and gave live demonstrations of the teleoperated, semi-autonomous and autonomous systems they are researching.

The introduction was made by ROBDEKON speaker Prof. Dr.-Ing. habil. Jürgen Beyerer. In his presentation, he explained, among other things, how the ALARA principle (»as low as reasonably achievable«), which has long been fundamental in radiation protection, thanks to technological advances in robotics can now be applied to other areas where humans would be exposed to chemical contamination or other hazards.

The application partners ICP Ingenieurgesellschaft Prof. Czurda und Partner GmbH, Kraftanlagen Heidelberg GmbH and Kerntechnische Hilfsdienst GmbH then went into more detail about the scenarios for which robot systems are being developed in ROBDEKON: the dismantling of nuclear facilities, the decontamination of plant components and waste, and the remediation of contaminated sites.

The FZI Research Center for Information Technology showed how mobile robots with legs and wheels can work together to recover hazardous materials. The researchers from Karlsruhe also taught an industrial robot arm to sort used batteries transported on an assembly line into collection containers depending on their type.

At the Karlsruhe and Ilmenau sites of the Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB, researchers are working, among other things, on autonomy kits that turn near-series construction machines into (partially) autonomous robots for the remediation of contaminated sites. A demonstration was given of how a driverless 24-ton excavator autonomously removes layers of soil and loads them onto the trailer of a tractor that also operates autonomously.

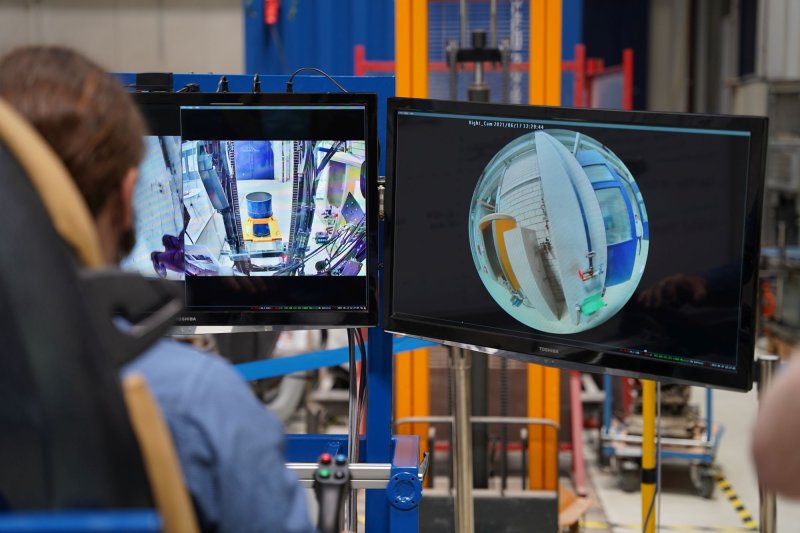

The Chair for Intelligent Sensor-Actuator Systems (ISAS) of the Karlsruhe Institute of Technology (KIT) presented the universal ROBDEKON interface, by means of which all control stations and robots developed in the project can be interconnected, as well as various innovative approaches for remote control and programming of manipulators.

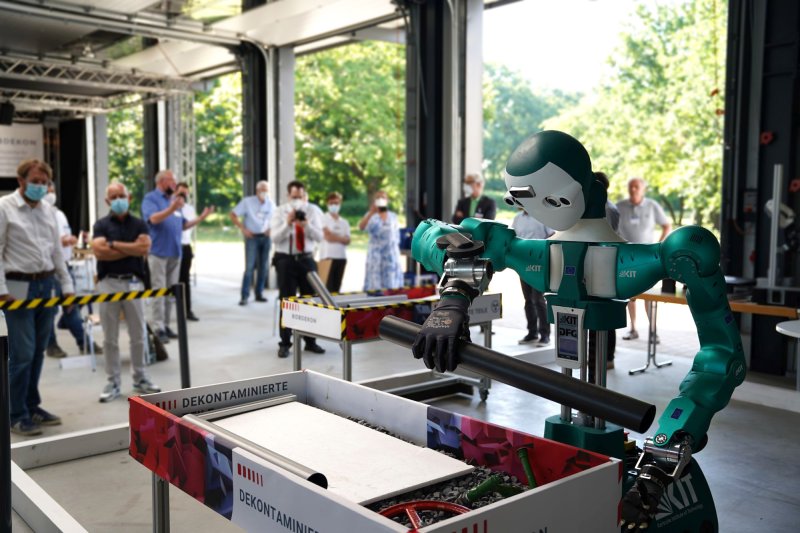

The developments of other participating KIT teams are aimed in particular at applications in the dismantling of nuclear power plants: The Chair of High-Performance Humanoid Technologies (H2T) demonstrated the capabilities of the ARMAR-6 humanoid robot to autonomously recognize and grasp plant components and to bring them to a defined deposit location.

The Chair of Intelligent Process Automation and Robotics (IPR) and the Institute for Technology and Management in Construction (TMB) jointly presented how the entire process of building decontamination can be covered by robots: First, GammaBot autonomously surveys the rooms, then another robot fully automatically mills off the top layer of concrete before it confirms the success of the decontamination by measuring possibly remaining radiation.

The industrial partner Götting KG demonstrated how a forklift truck can be controlled remotely by means of a specially developed control station; specifically, the transport of potentially contaminated barrels was demonstrated.

The contribution of the German Research Center for Artificial Intelligence (DFKI), which is also involved in ROBDEKON, was examined in advance on site in Bremen. Here, an automated walking excavator was demonstrated, which is being developed for the decontamination of landfills. The rover SHERPA and possibilities for telepresence in a »Virtual Reality Cave« were also presented.

ROBDEKON is funded by the German Federal Ministry of Education and Research as part of the »Research for Civil Security« program with 12 million Euros over an initial period of four years. The coordinator is Fraunhofer IOSB, where the ROBDEKON office is also located.